A Closer Look at KX7 Concaves

MaxThresh™ & MaxRound™ — the Perfect Pair

Helping You Be More Productive

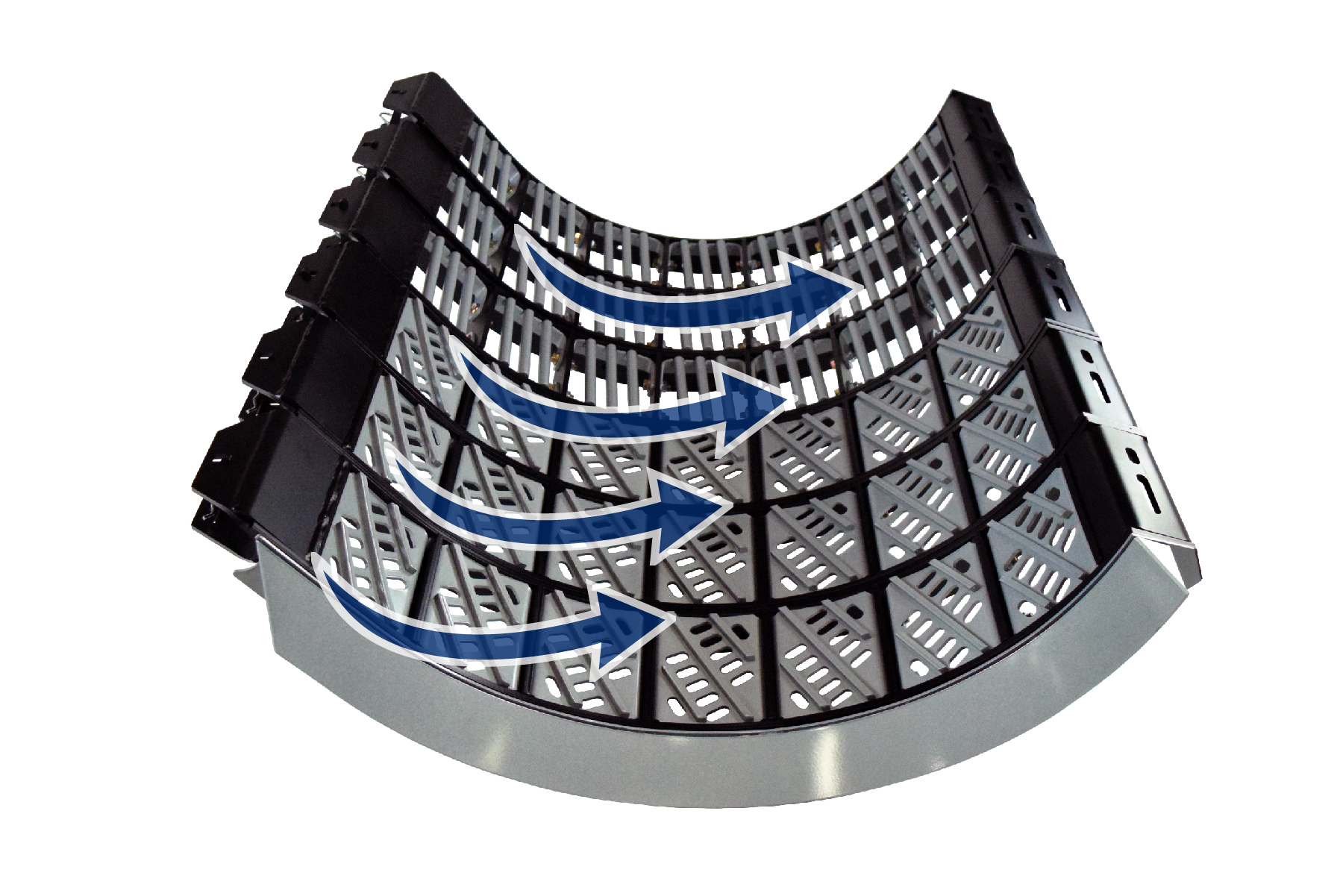

The angled-bar design of our KX7 MaxThresh and MaxRound box-style concaves meets the crop head on for more immediate threshing, which in turn increases the capacity of your combine. This allows you to raise your concave clearance, reduce wear to your rotor, and achieve more flexibility to finetune settings. With KX7, you’ll also gain more grain-on-grain threshing that results from increased airflow disruption.

Hear what KX7 users are saying

Greater Customization

KX7 concaves offer greater options to harvesters. At half the width of most traditional concaves, KX7 doubles your configuration options to best dial in your harvest. Choose from our MaxThesh and MaxRound concave assemblies, each with removeable, replaceable, and reversible box inserts. KX7 concaves offer the unique flexibility to customize your combine's threshing chamber by crop or field condition.

Configure KX7 for your crops & machine

Precision Product

All KX7 concaves are robotically manufactured, with welds individually inspected by American Welding Society (AWS)-qualified welders. Our ISO-certified quality assurance process includes rigorous visual and robotic testing to ensure each component meets or exceeds expectations for fit and performance.

KX7 MaxThresh concave assemblies feature a laser-cladding wear enhancement on the threshing bars to extend performance and life well beyond other high-wear options. MaxRound concave bars are heat-treated to gain a 25% improvement in wear resistance over non-heat-treated concaves.

KX7 MaxThresh concave assemblies feature a laser-cladding wear enhancement on the threshing bars to extend performance and life well beyond other high-wear options. MaxRound concave bars are heat-treated to gain a 25% improvement in wear resistance over non-heat-treated concaves.